Latest blogs

All recent blogs from British Sugar

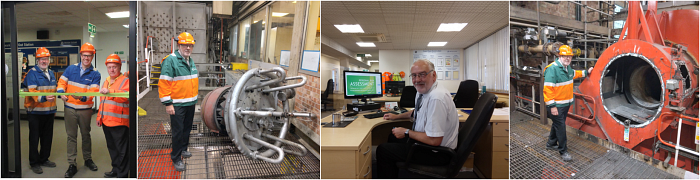

Celebrating 100 years of sugar production at Newark: An interview with Senior Project Manager Dave Papworth

22 July 2021

This year, our Newark factory is celebrating its centenary. Having opened its doors for sugar beet deliveries in 1921, September 2021 will see the start of the factory’s 100th campaign.

There aren’t many of our colleagues who have been around to see the majority of the last 100 campaigns, but one person heading towards that number is Senior Project Manager Dave Papworth, who has worked for British Sugar for 50 years – the last 20 of which at Newark. We caught up with Dave about his career and the changes he’s seen over his time with the business:

“I started working for what was then the British Sugar Corporation in September 1971. There were no interviews or tests in those days. My mother was a cleaner at British Sugar’s Bardney factory, so I just cycled down there and had a chat with one of the engineers, who took a copy of my school report. Then a few days later I had a letter through the post offering me a job as an apprentice. My first wage was £5.67 for a 40-hour week - back when fish and chips at the canteen were 7p!”

At the age of 15 and a half, and before he’d even finished his secondary education, Dave began his off-the-job training at what was then Ruston Gas Turbines training school in Lincoln. “I learnt all the basics I would need for my job at the factory – everything from chiselling to welding. It was a very industrial area and everything would stop at 4pm, but there was much less traffic than you’d see on a modern-day business park because we’d all go home by bike.”

Following his training, he went on to continue his apprenticeship at Bardney sugar factory in the engineering team. “I was working on turbines at first. I’ll always remember the Assistant Engineer I worked with because he was very traditional and wore a tie with his boiler suit. Perhaps that rubbed off on me, because you’ll still always find me in a tie today.”

“After my apprenticeship I started as a Shift Relief Engineer. At that time there were 300+ of us on site, which was reduced to about 60 by the time Bardney shut in 2001, because of the automation of the plant.”

“The processes haven’t changed though”, says Dave. “The sugar beet still comes in by lorry, we still need to wash it, remove any stones and slice it up. It’s just automated much more nowadays.”

One thing that is different though is the length of the sugar beet harvest, known as the ‘campaign’, which starts around mid-September. Dave tells us, “We used to only have one day off a month to try and get the campaign finished by Christmas. Today we carry on until the spring, or as late as necessary to get all the sugar beet in to the factory. Just last year with the bad weather and harvesting difficulties the farmers faced, Newark’s campaign ran until mid-April.”

“We can also process more sugar beet today – the amount of sliced beet we can get through our diffusers, where it’s mixed with hot water to extract the sugar, has increased by over 40 per cent. Back then we could only get 6,400 tonnes of beet sliced through the diffuser each day, and now we’re slicing an average of 9,100 tonnes per day. I used to record all this data by hand on a graph, before we had computers. It was the same with technical drawings for projects – I was appointed a Factory Draughtsman in 1980 and used to work with a team of 30 others across all the different factories to measure up the specifications for projects, then the team from head office would come and take them to draw up properly, then send back huge paper copies in the post. Now it’s all digital.”

“I think the achievement I’m most proud of over my career would be the project I was involved in to install a new boiler house and heavy fuel oil system at the factory, as well as a new 14MW turbine. This was completed in 1983 and was the first multi-million Pound project I was involved in. That was a huge investment at the time, and we’d never seen anything like it.”

In 2001, as well as studying for an engineering degree with the Open University, Dave moved to work at our Newark factory, as the site’s Engineering Services Manager. “During my time at Newark I’ve worked all over the factory – from projects to improve sugar beet presses at the start of the sugar making process, to increasing the capacity of the conveyor belts which move the finished sugar from the silos where it’s stored to the tankers we use to deliver it to our customers.”

He has also been privileged to supervise some apprentices himself over the years, and always encouraged them to keep learning. “My words of wisdom were that it’s never enough to just scrape through your assessments; if you know 40% of something, that means there’s 60% that you don’t know”, Dave explains. “I was quite strict with them! But it must have paid off because they’re now in Newark’s management team.”

Many of Dave’s memorable occasions on site have been related to the numerous British Sugar sports clubs which he’s taken part in over the years, including snooker, darts, football, cricket and even bowls. “We used to compete factory vs factory, so that was quite a lot of teams back when British Sugar had 18 factories, then the finals were at the head office in Peterborough. I’ve won trophies in all the sports I’ve played.”

After 50 years with the business, Dave will be leaving us in September to enjoy a well-earned retirement. Asked what he will miss most from British Sugar, Dave is clear: “the rice pudding from the canteen – can’t beat it. You can get more for your money with that compared to something that’s sliced and you only get one piece!” Getting value for money is clearly one of Dave’s talents; he’s used the same office chair for almost 40 years. “I brought it to Newark from Bardney – it’s brilliant! The wheels just aren’t the same on new ones!”

On his plans for retirement, he told us “My wife is retiring this year too and has a long list of jobs waiting for us! But I’m looking forward to a bit of fair-weather fishing and golf too.” We wish Dave all the very best for his next endeavours.