An industry first - visibility of the whole beet supply chain

1 October 2025

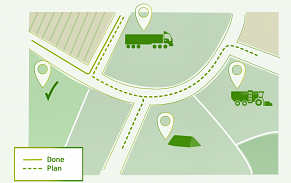

The 2022/23 campaign saw the launch of two initiatives – “Lifted” and “Delivered” – to improve the campaign for everyone, as part of the Field to Factory Partnership.

Both fledgling systems have been upgraded and fine-tuned by platform developers HSAT, ready for the forthcoming campaign. Following clear feedback from harvesters and hauliers, “Lifted” and “Delivered” users can now see overhead powerlines in relation to mapped fields and clamps.

“Lifted” is an app for harvester operators which maps the fields they are lifting to create a digital harvesting record. The app aids campaign planning, navigation from field to field, and record-keeping, while helping to make sure beet is delivered to factory efficiently.

This year British Sugar is retrofitting tablets in harvester cabs so that drivers benefit from a larger screen that’s easier to use, with navigation and progress reporting all in one place.

Meanwhile, “Delivered” - the web portal for hauliers – shares field maps and clamp locations, along with estimated tonnages from the harvester. Once a clamp has been cleared, the system creates a digital record.

What's new this campaign?

Roughly one in five growers have the opportunity to join the pilot of “Loaded”. The new system is designed to give growers better information about their crop’s performance at harvest, while helping hauliers and British Sugar plan campaign logistics, and manage clamps and factory supply more effectively.

From the beginning of this campaign, participating growers will work with five hauliers to test out the system which uses Radio Frequency Identification (RFID) tags. The tags link sugar beet deliveries arriving at the factory back to the clamp they were loaded from.

The RFID tags are attached to each trailer and lorry, while a sensor fitted to the loader reads the trailer tag as the loading is taking place. Once the haulier arrives at the factory, another sensor reads the tag on the lorry and the trailer after it’s weighed.

Cross-industry benefits

This system allows each load to be traced back to the exact clamp and field(s) that it was harvested from. Growers will be able to see all the information in an end-of-campaign report, offering valuable data including yield and sugar content at field/block level.

As well as giving growers a clearer picture of how each field has performed, it is hoped that the pilot will make for more efficient management of roadside stocks during the campaign.

“Feedback from the growers and hauliers taking part in this pilot will be an important part in what happens next with Loaded,” explains Simon Jervis, British Sugar’s Head of Agriculture Performance.

“Results will be reviewed during and after the campaign. If it's successful, we will look at how to make improvements and how to roll it out more widely. This is a joint initiative owned by everyone from grower, harvester, haulier, and factories, so any decisions will continue to be made collaboratively based on feedback from all industry partners”.

Dan Green, Agriculture Director at British Sugar comments: "For the first time in our history, we now have visibility of our whole beet supply chain, from field to factory. It's a huge step forward in our agriculture transformation journey, and one that we're excited about. The ultimate aim is to improve campaign for everyone."