Delivery plan pilot aims to improve Campaign for everyone

29 September 2023

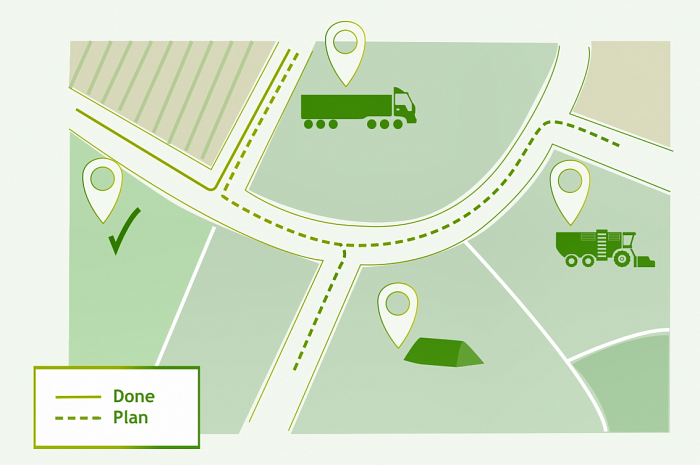

Following months of grower, harvester and haulier feedback and working collaboratively as an industry to design improved ways of working, a new delivery plan is being piloted during the 2023/24 Campaign, with the ambition to roll-out nationwide in the future.

“The adaptable plan produces a delivery schedule for a haulier close to every grower’s ideal schedule”

The ‘adaptable campaign plan’ is a crucial component of the Field-to-Factory Partnership, launched to the sugar beet industry at the start of 2022 to create a campaign that works for everyone. It is divided into four workstreams focusing on precise planning, improving information availability, involvement and fairness. Having spent the first twelve months of the project listening to farmers, hauliers and harvesting contractors, the team behind the Field-to Factory Partnership is determined to start tackling the issues identified.

Leading the way will be the growers, harvesters, hauliers and British Sugar colleagues involved in the adaptable campaign plan pilot this coming Campaign. “We will create a pre-campaign running order for the pilot haulage groups based on a logic considering parameters like a field's soil type and the planned following crop,” says Justin Fletcher, Strategic Project Manager and initiative lead for the adaptable campaign plan. “We want every grower in the pilot haulage groups to have a delivery plan for every field which is as close as possible to the one they requested when they submitted their crop declaration, and for this to be geographically optimised to make it efficient for the haulier. The aim is to maximise satisfaction.”

Growers may have noticed they were asked in this season’s Crop Area Declaration when they planned to harvest and deliver their fields. This was so the project team could calculate an unconstrained plan, the sum of every grower’s ideal delivery period for their fields. “Using this data as a starting point, we believe the adaptable plan can maximise grower satisfaction by producing a delivery schedule for a haulier as close as possible to every grower’s ideal schedule,” explains Matt Evans, British Sugar Account Manager and project team member.

“A shared, visible and optimised plan will assist harvesters and hauliers to plan their customer’s needs much sooner than they do now.”

The next step is to confirm the pilot hauliers and then to speak with the growers in their haulage groups, says Justin. To optimise the unconstrained plan, the team must establish the intended following crop and loading location of each of the grower's fields. “It is important for growers to understand that just because they may be growing sugar beet on light land and intend to plant a spring crop after their sugar beet, the adaptable campaign plan should not force them to deliver it late if that is something they do not plan to do,” adds Matt.

The vital step in the process is the calculation involved in optimising the unconstrained plan into the adapted pre-campaign plan. To do this, the team has partnered with a data and technology business to develop a bespoke system which generates the plan based on a weighted set of parameters. “First, it factors in the soil type and the following cropping,” says Justin. “This gives us a running order of fields to guide the haulier on which fields to deliver and when. The system then considers the loading location to optimise a haulier’s route from field-to-field, maximising their efficiency.”

“This is not necessarily anything different to how a haulage group manages itself in a Campaign,” points out Matt. “The critical difference is that a plan for the whole campaign will be laid out before the factories open, which will be visible to everyone in the pilot haulage group. It is about growers and hauliers having advanced access to information, enabling them to make informed business decisions.

“Our feedback from the potential pilot scheme hauliers is that they can all benefit differently. Some are excited about having a structured planning process. Others feel they already have this but could benefit from optimised route planning.”

An objective of the pilot is to link the optimised campaign plan with harvesting contractors. They can often experience significant peaks of workload combined with weather windows and when growers want to sow the next crop. The team expect the optimisation for the haulage groups to deliver similar efficiencies for harvesting contractors. A shared, visible and optimised plan at the start of the campaign will assist them to plan their customer’s needs much sooner than they do now.

Linked to the adaptable campaign plan is bulk logistics optimisation, another project within the Field to Factory partnership. Justin sees this as the in-campaign execution of the optimised plan. It should be able to cope with external factors such as the weather or factory performance, which can influence a plan developed before the Campaign begins. In due course, the team expect to have the ability to rerun the adaptable campaign plan if there is a significant event in the Campaign.

“The pilot intends to prove that adaptable campaign planning is possible, to test the logic behind the calculation creating the running order and to learn for coming campaigns,” explains Justin. “What we have developed so far is a ‘minimum viable product’, which should solve the core problem but does not have all the functionality we expect the final solution to have.”

The team are already thinking about what advancements they would like to make for the 2024-25 campaign, adapting to the learnings from this season. For now, their focus is on progressing towards the Field-to-Factory Partnership’s objective of creating a Campaign that works for everyone. “We spent a long time listening to industry stakeholders’ views; now we’re starting to deliver on the feedback. The adaptable camping plan pilot is a vital first step in this process,” concludes Justin.